- Mon to Fri 9:00am to 6:00pm

- +91-9930066862

- info@metaaerospaces.com

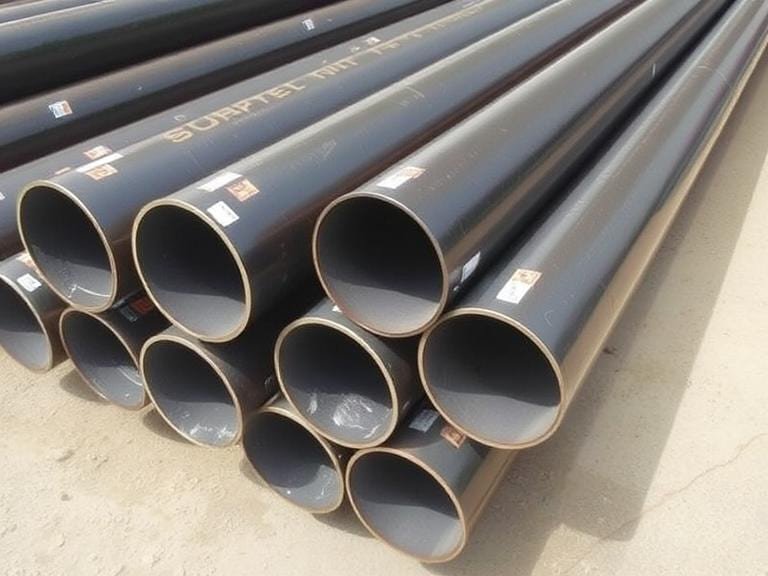

ASTM A671 CC65 pipes is a high-grade electric-fusion-welded steel pipe for pressure vessels to be used in high and moderate temperature applications. Manufactured from pressure vessel-grade steel, ASTM A671 CC65 Pipes have high tensile strength, durability, and resistance to corrosion. ASTM A671 CC65 Pipes find extensive use in oil and gas, petrochemical, power generation, and shipbuilding industries, where high structural integrity is needed.

Table of Content

ASTM A671 CC65 Carbon pipe is a low-carbon steel pipe produced through electric fusion welding (EFW). It undergoes stringent tests such as ultrasonic tests, radiography, and hydrostatic pressure tests to deliver improved performance in tough conditions. Seamless and welded pipes are available for low-pressure and high-pressure applications.

Meta Aerospace is a trustworthy Carbon ASTM A671 CC65 Pipes Suppliers that offers superior performing pipes that meet the highest industrial standards.

Carbon ASTM A333 Gr. 1 pipe is widely used in oil refining and gas processing plants due to its ability to withstand low temperature and high pressure.

Preferred in mechanical applications for use in machinery components and industrial pipe systems.

Meta Aerospace is a prominent Carbon ASTM A671 CC65 Pipes Manufacturer supplying high-performance welded pipes for industrial use. With modern production facilities and stringent quality control, we assure that our products meet international specifications such as ASTM, ASME, and API.

Global Carbon ASTM A671 CC65 Pipes Suppliers One of the most reliable Carbon ASTM A671 CC65 Pipes Suppliers, Meta Aerospace provides high-quality pipes made from carbon steel to industries in Europe, Middle East, Asia, and North America. We provide customized products as per client specifications with material of high standard and timely delivery.

Largest Carbon ASTM A671 CC65 Pipes Stockists Meta Aerospace is a leading Carbon ASTM A671 CC65 Pipes Stockists with a vast inventory of EFW pipes in a variety of sizes, thicknesses, and grades.

Whether you need pipes for high temperature or low pressure applications, we have a solution for you. Leading Exporter Of Carbon ASTM A671 CC65 Pipes Being one of the renowned Carbon ASTM A671 CC65 Pipes Exporters, Meta Aerospace provides industries across the world with high-grade carbon steel pipes. With expertise in export and logistics, we provide seamless and trouble-free delivery to any part of the world.

| Type | ASTM A671 Gr. CC65 LSAW / SAW / EFW PIPE | |

|---|---|---|

| Executive Standard | API SPEC 5L, GB/T 9711.1, GB/T 9711.2, GB/T 9711.3, SY/T5037 | |

| ASTM A671 |

Standard Specification for Electric-Fusion-Welded Steel Pipe for Atmospheric and Lower Temperatures |

|

| ASTM A672 | Standard Specification for Electric-Fusion-Welded Steel Pipe for High-Pressure Service at Moderate Temperatures | |

| Class Designation | Class 10, 11, 12, 13, 20, 21, 22, 23, 30, 31, 32, 33, 34, 40, 41, 42, 43, 50, 51, 52, 53, 60, 61, 62, 63, 70, 71, 72, 73. | |

| Size | Outer Diameter | Seamless 17-914mm 3/8-36 inch LSAW 457-1422mm 18-56 inch |

| Wall Thickness | 2-60mm SCH10 SCH20 SCH30 STD SCH40 SCH60 XS SCH80SCH100 SCH120 SCH140 SCH160 XXS |

|

| Length | Single random length / Double random length5m-14m, 5.8m, 6m, 10m-12m, 12m or as customer’s actual request | |

| Ends | Plain end/Beveled, protected by plastic caps on both ends, cut quare, grooved, threaded and coupling, etc | |

| Surface Treatment | Bare, Painting black, varnished, galvanized, anti-corrosion PE PP / EP / FBE coating |

|

| Technical Methods | Hot-rolled / Cold-drawn / Hot-expanded | |

| Testing Methods | Eddy current testing, Hydrostatic testing or Ultrasonic examination, NDT and also with chemical and physical property inspection | |

| Packaging | Small pipes in bundles with strong steel strips, large pieces in loose; Covered with plastic woven bags; Suitable for lifting operation; Loaded in 40ft or 20ft container or in bulkAlso according to customer’s requests | |

| Application | Conveying oil, gas and water | |

| MOQ | 1 ton | |

| Production Capacity | 5000 T/M | |

| Delivery Time | Within 2 Weeks | |

| Specification | Steel grade | Chemical composition | Remarks | |||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Ti | |||

| Pipes for pressure service ASTM A671, A672 |

-/A45 |

-/0.17 |

- |

0.98 |

0.035 |

0.035 |

- |

A671/ A672 |

|

-/A50 |

-/0.22 |

- |

||||||

|

CA55/A55 |

0.28 |

- |

||||||

|

-/B55 |

-/0.20 |

0.13 ~0.45 |

||||||

|

CB60/B60 |

0.24 |

|||||||

|

CB65/B65 |

0.28 |

|||||||

|

CB70/C70 |

0.31 |

1.30 |

||||||

|

-/C55 |

-/0.18 |

0.55 ~0.98 |

||||||

|

CC60/C60 |

0.21 |

|||||||

|

CC65/C65 |

0.24 |

0.79 ~1.30 |

||||||

|

CC70/C70 |

0.27 |

|||||||

| Products | Steel Grade | BASE METAL MECHANICAL COMPOSITION | Welding point tensile strength (N/mm2) | Remarks | |||

|---|---|---|---|---|---|---|---|

| Yield point (N/mm2) | Tensile Stregth (N/mm2) | Test Pieces | Elongation (%) | ||||

|

Pipes for pressure service ASTM A671, A672

|

-/A45

|

-/165

|

-/310~450

|

-

|

-/30

|

-/310~450

|

A671/ A672

|

|

-/A50

|

-/185

|

-/345~485

|

-/28

|

-/345~485

|

|||

|

CA55/A55

|

205

|

380~515

|

27

|

380~515

|

|||

|

-/B55

|

-/205

|

-/380~515

|

-/27

|

-/380~515

|

|||

|

CB60/B60

|

220

|

415~550

|

25

|

415~550

|

|||

|

CB65/B65

|

240

|

450~585

|

23

|

450~585

|

|||

|

CB70/B70

|

260

|

485~620

|

21

|

485~620

|

|||

|

-/C55

|

-/205

|

-/380~515

|

-/27

|

-/380~515

|

|||

|

CC60/C60

|

220

|

415~550

|

25

|

415~550

|

|||

|

CC65/C65

|

240

|

450~585

|

23

|

450~585

|

|||

|

CC70/C70

|

260

|

485~620

|

21

|

485~620

|

|||

Carbon ASTM A671 CC65 Pipes price, Carbon ASTM A671 CC65 Pipes specification, Carbon ASTM A671 CC65 Pipes mechanical properties, Carbon ASTM A671 CC65 Pipes chemical composition, Carbon ASTM A671 CC65 Pipes weight chart, Carbon ASTM A671 CC65 Pipes equivalent grades, Carbon ASTM A671 CC65 Pipes hardness, Carbon ASTM A671 CC65 Pipes tensile strength, Carbon ASTM A671 CC65 Pipes manufacturers in India, Carbon ASTM A671 CC65 Pipes dealers, Carbon ASTM A671 CC65 Pipes exporters in UAE, Carbon ASTM A671 CC65 Pipes distributors, Carbon ASTM A671 CC65 Pipes suppliers in USA, Carbon ASTM A671 CC65 Pipes uses, Carbon ASTM A671 CC65 Pipes applications.

India

India United States

United States Saudi Arabia

Saudi Arabia Kuwait

Kuwait Singapore

Singapore Malaysia

Malaysia UAE

UAE Germany

Germany Italy

Italy China

China UK

UK Canada

Canada Iran

Iran Thailand

Thailand South Korea

South Korea Turkey

Turkey Morocco

Morocco Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines Egypt

Egypt Japan

Japan Russia

Russia Vietnam

Vietnam Australia

Australia Qatar

Qatar South Africa

South Africa Portugal

Portugal Oman

Oman Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Netherlands

Netherlands Indonesia

Indonesia Mexico

Mexico Brazil

Brazil France

France Taiwan

Taiwan Nigeria

Nigeria Bangladesh

Bangladesh Iraq

Iraq Ukraine

Ukraine Poland

Poland Romania

Romania Cyprus

Cyprus Angola

Angola Colombia

Colombia Norway

Norway Chile

Chile Tobago

Tobago Greece

Greece Czechia

Czechia Belgium

Belgium Sri Lanka

Sri Lanka Myanmar

Myanmar Venezuela

Venezuela