- Mon to Fri 9:00am to 6:00pm

- +91-9930066862

- info@metaaerospaces.com

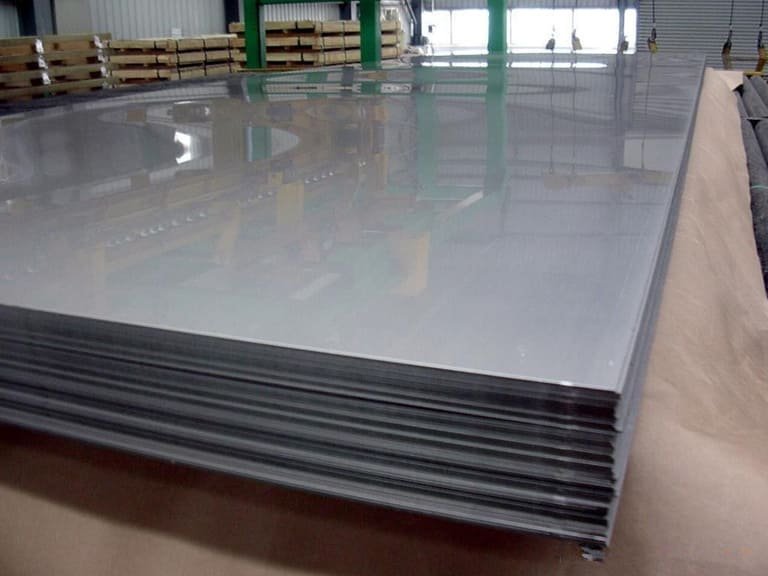

Meta Aerospace is a reputable company in the metal sector with a long history of providing high-quality industrial material that serves critical industries. One of their high-profile products is Super Duplex Steel S32750 Plates, which are built to perform under harsh conditions. They are manufactured for strength, durability, and resistance to highly corrosive substances, which qualifies them for heavy-duty industrial use.

Table of Content

Super Duplex Steel S32750 Plates are a high-quality alloy of stainless steel that employs the properties of austenitic steel with ferritic steel. They have an optimized mix of chromium, molybdenum, and nitrogen that imparts them with extraordinary mechanical strength coupled with corrosion resistance. They are commonly known for their outstanding pitting resistance along with crevice corrosion resistance in chloride-containing environments like chemical process industries or marine environments.

Super Duplex Steel S32750 Plates is their two-phase microstructure. This microstructure increases their strength and ductility with consistent resistance to stress corrosion cracking. Their outstanding welding properties and formability make it possible for fabricators to utilize them in any desired configurations. They possess low thermal expansion with high thermal conductivity, suitable for use under high temperatures and pressures.

Being premier Super Duplex Steel S32750 Plates Suppliers, Meta Aerospace maintains an enormous stock of different sizes, thicknesses, and surface treatments to support a clientele that spreads globally. It supplies sheets with appropriate mill test certifications to assure transparency and product integrity at all levels.

Customers from various industries count on Meta Aerospace for a strong chain of supplies and product availability assurance. One of the major positives of Super Duplex Steel S32750 Plates is their tensile and yield strength, which is greater than that of standard duplex and austenitic stainless steels. These sheets provide economical solutions in long-term service, eliminating the costs associated with costly replacements and repairs. Their strong resistance to sulfide stress corrosion, erosion, and fatigue render them suitable for harsh operating environments.

The high tensile Super Duplex Steel S32750 Plates is used in various industries due to its better mechanical profile:

Meta Aerospace is one of the most trusted Super Duplex Steel S32750 Plates Manufacturers that ensures consistency in quality, precision in dimensions, and timely delivery. They produce all products in accordance with international standards like ASTM A240 and UNS S32750. These sheets are easily machinable, can be cut, welded, and formed, so are extremely flexible in production.

Meta Aerospace is also known to be one of the reliable Super Duplex Steel S32750 Plates Stockists with ready stock of standard, special, and customized sizes. Whether it is an original equipment manufacturer purchase or a special requirement, customers enjoy responsive delivery capabilities, prompt dispatch, and protective packaging services that preserve product integrity during transit.

Being global Exporters of Super Duplex Steel S32750 Plates, Meta Aerospace caters to clients from the Middle-East, Europe, Asia, and Africa. The company follows rigorous export procedures and documentation practices that ensure smooth logistics on an international level. Sheets are packed with care and exported with full traceability and export compliance.

| Specification | ASTM A240 / ASME SA240 |

|---|---|

| Length | 2000 mm / 2440 mm / 2500 mm / 3000 mm / 6000 mm. |

| Width | 1000mm / 1219mm /1250mm / 1500mm / 2000mm |

| Thickness | Ranging from 0.3mm to 20mm |

| Hardness | As per ASME A & NACE MR 175 |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR) |

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| Super Duplex Steel | 1.4410 | S32750 / S32760 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Super Duplex Steel S32750 | 0.030 max | 1.20 max | 0.80 max | 0.035 max | 0.020 max | 24 – 26 | 3 – 5 | 6 – 8 | 0.24 – 0.32 | 58.095 min |

| Super Duplex Steel S32760 | 0.05 max | 1 max | 1 max | 0.030 max | 0.010 max | 24 – 26 | 3 – 4 | 6 – 8 | 0.20 – 0.30 | 57.61 min |

| Density | Melting Point (°C) | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 7.8 g/cm 3 | 1350 °C (2460 °F) | Psi – 80000 , MPa – 550 | Psi – 116000 , MPa – 800 | 15 % |

Super Duplex Steel S32750 Plate Price, UNS S32750 Plate Suppliers, ASTM A240 Super Duplex Plates, Super Duplex Steel Plates, S32750 Cold Rolled Plates, Super Duplex Hot Rolled Plates, Super Duplex 2507 Plates, Super Duplex Plate Stockists India, Duplex Steel Plates Exporters, Super Duplex Stainless Steel Plates, Corrosion Resistant Duplex Plates, Duplex Steel Plate Manufacturer Mumbai, High Tensile Duplex Plates, Super Duplex Steel S32750 Plate Weight Chart, Super Duplex Coil, S32750 Plate Thickness, Industrial Duplex Plates, Duplex Steel S32750 Flat Plates, Super Duplex Steel Plate Traders, Duplex Steel Plates for Marine, S32750 Plates for Oil & Gas, Super Duplex Steel Plate Dimensions, Duplex 32750 Plates for Chemical Plants, 32750 Plates for Power Plants, UNS S32750 Plates, Super Duplex Steel Plate Chemical Composition, Duplex 32750 Plate Hardness, Super Duplex Plate Mechanical Properties, Super Duplex Steel Price List.

India

India United States

United States Saudi Arabia

Saudi Arabia Kuwait

Kuwait Singapore

Singapore Malaysia

Malaysia UAE

UAE Germany

Germany Italy

Italy China

China UK

UK Canada

Canada Iran

Iran Thailand

Thailand South Korea

South Korea Turkey

Turkey Morocco

Morocco Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines Egypt

Egypt Japan

Japan Russia

Russia Vietnam

Vietnam Australia

Australia Qatar

Qatar South Africa

South Africa Portugal

Portugal Oman

Oman Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Netherlands

Netherlands Indonesia

Indonesia Mexico

Mexico Brazil

Brazil France

France Taiwan

Taiwan Nigeria

Nigeria Bangladesh

Bangladesh Iraq

Iraq Ukraine

Ukraine Poland

Poland Romania

Romania Cyprus

Cyprus Angola

Angola Colombia

Colombia Norway

Norway Chile

Chile Tobago

Tobago Greece

Greece Czechia

Czechia Belgium

Belgium Sri Lanka

Sri Lanka Myanmar

Myanmar Venezuela

Venezuela