- Mon to Fri 9:00am to 6:00pm

- +91-9930066862

- info@metaaerospaces.com

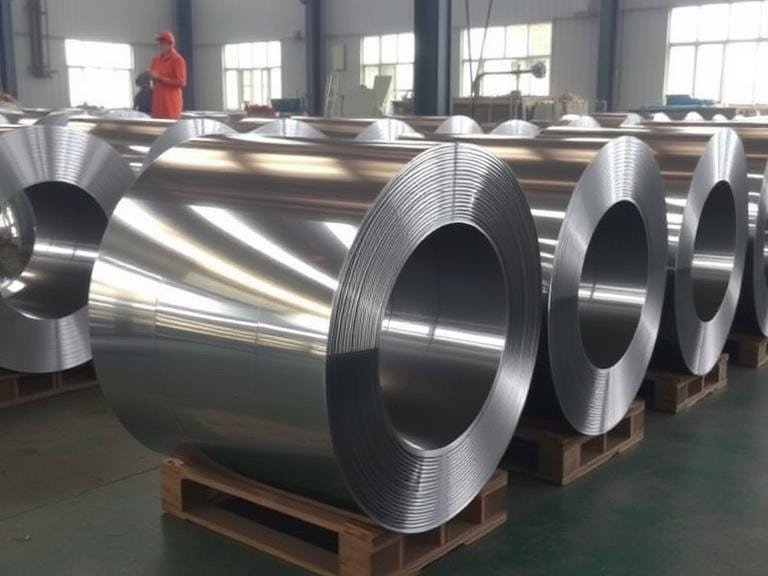

Meta Aerospace is a world leader in high-performing alloys, featuring a diverse line of high-quality products that will survive the toughest environments. Of the top-shelf products we carry, Hastelloy C22 Coils are the best when it comes to corrosion and mechanical strength. These coils are specially designed to operate in harsh chemical processing conditions, and they are the top choice of many industries. Made to precise specifications and inspected for quality, Hastelloy C22 Coils by Meta Aerospace provide long-term reliability and outstanding performance under the toughest conditions.

Table of Content

These are flat metal strips of Hastelloy C22, a composition of a nickel-chromium-molybdenum alloy, having exceptional resistance to oxidizing and reducing agents. This special composition makes them versatile and effective in corrosion resistance under hostile conditions. By including elements of iron and tungsten in the composition, these coils provide enhanced structural stability and immunity against pitting, crevice corrosion, and stress corrosion cracking. Hastelloy C22 Coils Manufacturers like Meta Aerospace aim to produce products in compliance with international standards in order to deliver maximum reliability to the end use.

One of the key benefits of Hastelloy C22 Coils is that they resist harsh conditions without compromising structural stability. These coils are highly resistant to a diverse set of chemical environments, including harsh oxidizers such as ferric acids, chlorine, and moist chlorine gas. They also have high resistance to seawater and brine solutions, and hence they are the best choice for marine and offshore use. Meta Aerospace, a top Hastelloy C22 Coils Supplier, makes every coil undergo rigorous quality checks in order to ensure maximum resistance and hardness.

Their exceptional fabricability and weldability also increase their compatibility in the case of complex assemblies and processes of fabrication. The exceptional properties of Hastelloy C22 Coils render them extremely useful in a wide variety of industrial processes. In the chemical processing sector, they are also extensively applied in reactors, heat exchangers, and storage tanks due to being highly resistant to acidic and chlorinated conditions. In marine engineering, they are applied in shipbuilding parts involving saltwater exposure, delivering long-term corrosion protection. Hastelloy C22 Coils Stockists such as Meta Aerospace provide consistent stock to cater to timely industrial needs. In the paper and pulp sector, they are applied in bleach plants where chemicals are aggressive and require highly corrosion-resistant material.

Due to the strong build and high tensile resistance of Hastelloy C22 Coils, they are applied in a wide variety of high-stress and high-temperature conditions. Some of the significant uses and applications are listed below:

We are one of the best Hastelloy C22 Coils Suppliers, which deliver at a faster pace and at a reasonable price. They are in high demand in heat exchanges, condenser systems, pickling machinery, acid manufacturing, and pollution control equipment. They are smoothly compatible with a variety of joining and shaping processes, which makes them a choice in engineering and infrastructure projects.

From a technical perspective, Hastelloy C22 Coils Stockists serve the thermal stability demands of industries. They find employment in furnace parts, heat exchangers, petrochemical processing, power generation, and nuclear reactors. Their high creep and rupture properties keep them running smoothly in pressure vessels and steam generator tubes. Meta Aerospace holds a wide variety of coils in different thicknesses and sizes to serve the needs of different projects.

With decades of knowledge and advanced infrastructure, Meta Aerospace remains a preferred supplier of choice to industries requiring high-quality and high-performing Hastelloy C22 Coils. Unparalleled quality, innovation, and customer-centricity are the hallmarks at Meta Aerospace that put it in a class of its own in the international market. We provide customized coil options in thickness, width, and finish to suit the specific needs of diverse applications. Be it aggressive chemical exposure or high temperature use, our coils deliver top performance every time.

| Specifications : | ASTM B575 / ASME SB575 |

|---|---|

| Standard : | ASTM, ASME and API |

| Size : | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness : | 1.0mm – 200mm |

| Range : | 5 mm To 50 mm thick in 1000 mm TO 1250 mm width & 2500 mm Length. |

| Production : | Hot-Rolled (HR) / Cold-Rolled (CR) |

| Form : | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

| Grade : | Hastelloy C22 Sheets, Plates & Coils UNS (N06022), DIN (2.4602) |

| STANDARD | UNS | WNR. | AFNOR | EN | JIS |

|---|---|---|---|---|---|

| Hastelloy C22 | N06022 | 2.4602 | - | NiCr21Mo14W | NW 6022 |

| Grade | Ni | C | Mo | Mn | Si | Fe | P | S | Co | Cr | W | V |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hastelloy C22 | Balance | 0.010 max | 12.5-14.5 | 0.50 max | 0.08 max | 2-6 | 0.02 max | 0.02 max | 2.5 max | 20-22.5 | 2.5-3.5 | 0.35 max |

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Hastelloy C22 | 8.69 g/cm3 | 1399 °C (2550 °F) | Psi – 1,00,000, MPa – 690 | Psi – 45000, MPa – 310 | 45 % |

Hastelloy C22 Slit Coils, ASTM B575 Hastelloy Coils, Nickel Alloy C22 Coils, UNS N06022 Coils, Hastelloy Alloy C22 Coils, Alloy C22 Coils, Hastelloy C22 Cold Rolled Coils, Hastelloy C22 Hot Rolled Coils, Hastelloy C22 Coil Stockist, Hastelloy C22 Strip Coils, Hastelloy C22 Coil Price, Hastelloy C22 Coil Dealers, Hastelloy C22 Export Quality Coils, C22 Alloy Industrial Coils, Corrosion Resistant Hastelloy Coils, Hastelloy C22 Precision Coils, Hastelloy C22 Coil Suppliers in India, Hastelloy C22 Coil Weight Chart, Hastelloy C22 Foil Coil, Hastelloy C22 Coil Dimensions, Hastelloy C22 Coils Distributors, Hastelloy C22 Perforated Coils, Hastelloy C22 Sheet Coil, Hastelloy C22 Coil Fabricators, Hastelloy C22 Coils Wholesalers, Hastelloy C22 Coils for Chemical Industry, Hastelloy C22 Marine Coils, Hastelloy C22 Anti-Corrosive Coils, High Performance Alloy Coils, Hastelloy C22 Industrial Applications, Hastelloy C22 Pickled Coils, Hastelloy C22 Coil Export to UAE, Hastelloy C22 Coil Ready Stock, Hastelloy C22 Coils for Petrochemical, Hastelloy C22 Coils for Oil & Gas.

India

India United States

United States Saudi Arabia

Saudi Arabia Kuwait

Kuwait Singapore

Singapore Malaysia

Malaysia UAE

UAE Germany

Germany Italy

Italy China

China UK

UK Canada

Canada Iran

Iran Thailand

Thailand South Korea

South Korea Turkey

Turkey Morocco

Morocco Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines Egypt

Egypt Japan

Japan Russia

Russia Vietnam

Vietnam Australia

Australia Qatar

Qatar South Africa

South Africa Portugal

Portugal Oman

Oman Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Netherlands

Netherlands Indonesia

Indonesia Mexico

Mexico Brazil

Brazil France

France Taiwan

Taiwan Nigeria

Nigeria Bangladesh

Bangladesh Iraq

Iraq Ukraine

Ukraine Poland

Poland Romania

Romania Cyprus

Cyprus Angola

Angola Colombia

Colombia Norway

Norway Chile

Chile Tobago

Tobago Greece

Greece Czechia

Czechia Belgium

Belgium Sri Lanka

Sri Lanka Myanmar

Myanmar Venezuela

Venezuela