- Mon to Fri 9:00am to 6:00pm

- +91-9930066862

- info@metaaerospaces.com

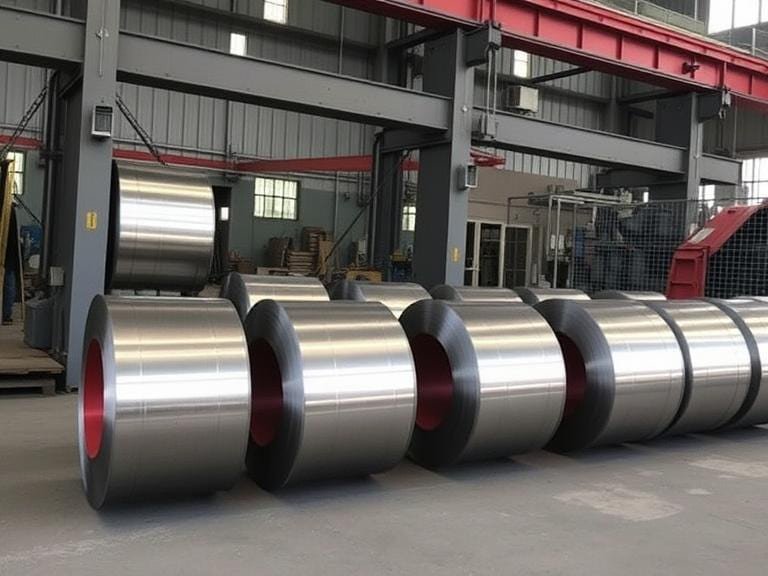

Inconel 718 Coils are amongst the most versatile and high-performing of the nickel-chromium alloys applied in rigorous industrial processes. Meta Aerospace is a name to trust in the provision of these precision-coiled products that meet the stringent needs of the aerospace, automotive, marine, and energy industries. Highly resistant to oxidation and corrosion, Inconel 718 Coils are best suited in harsh temperature and mechanical stressing conditions. Due to a one-of-a-kind blend of workability and resilience, these coils are best suited to a variety of fabrications and structural uses.

Table of Content

Inconel 718 Coils is the excellence of their composition. This is composed mainly of chromium and nickel, supplemented by considerable additions of molybdenum, niobium, and iron. This composition makes the material have improved mechanical strength, weldability, and stress-corrosion properties. Inconel 718 also possesses the ability to harden by precipitates, which helps it retain its strength in high-temperature conditions, thus becoming a favorite of the power and aeronautical industries. Its ability to resist post-weld cracking, oxidation, and creep deformation makes it stand out from the other nickel-based alloys.

Meta Aerospace is one of the best Inconel 718 Coils Manufacturers in the market globally. We use sophisticated manufacturing techniques that guarantee dimensional accuracy, uniformity, and consistent functionality in every supplied coil. For commercial use or customized engineering projects, the Inconel 718 coils we produce are manufactured in line with international standards such as ASTM B670 and AMS 5596. These coils have the ability to operate at up to 700°C temperature without compromising mechanical properties, minimizing the need for frequent maintenance and prolonging the service life.

Another distinct feature that makes Meta Aerospace a choice of preference amongst Inconel 718 Coils Suppliers is the quality assurance we give prime importance to. We conduct rigorous tests like ultrasonic testing, intergranular corrosion tests, and tensile testing for quality checks before we ship the products out. Inconel 718's hardness and strength properties are not compromised even in the longest operating environments, and that makes these coils the perfect choice to use in the components of turbojet engines, heat exchangers, and pressure vessels.

Due to the strong build and high tensile resistance of Inconel 718 Coils, they are applied in a wide variety of high-stress and high-temperature conditions. Some of the significant uses and applications are listed below:

One of the highly demanded uses of Inconel 718 coils is their capability to supply elevated tensile strength in harsh conditions. These coils retain their hardness and structural integrity in cryogenic to high-temperature conditions, and hence, they find specific use in the aeronautics field in areas including the manufacture of turbine blades, rocket motors, and thrust reversers.

Meta Aerospace established a solid reputation as one of the top Inconel 718 Coils Stockists by holding a ready and large stock to serve the urgent and bulk needs of customers. We provide custom shearing, slitting, and surface finishing options as per customer specifications. Be it a large volume to meet industrial demands or a special solution for a given use, our ready stock and quick shipping enable us to be a reliable business companion.

Well-known internationally, Meta Aerospace is also one of the top Inconel 718 Coils Exporters, exporting high-quality coils to destinations in Europe, Asia, and the Middle East. We use a highly effective logistics system, and our export packaging conveys the shipment in compliance with international shipping regulations in order to keep the material safe during transit.

| Specifications: | ASTM B168 / ASME SB168 |

|---|---|

| Dimensions: | ASTM, ASME, and API |

| Width: | 1000 mm, 1219 mm, 1500 mm, 1800 mm, 2000 mm, 2500 mm, 3000 mm, 3500 mm, etc |

| Thickness: | 4 mm - 100 mm |

| Length: | 2000 mm, 2440 mm, 3000 mm, 5800 mm, 6000 mm, etc |

| Surface Finish: | 2 B, 2 D, BA, NO .1, NO .4, NO .8, 8 K, hairline, sand blast, Brush, etching, Hot rolled plate(HR), Cold rolled Coil(CR), SATIN(Met with Plastic Coated) etc |

| Hardness: | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

| Form: | Coils, Foils, Rolls, Plain Coil, Shim Coil, Strip, Flats, Blank(Circle), Ring(Flange) etc. |

| Grade | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| Inconel 718 | 2.4668 | N07718 | NCF 718 | - | - | - | - |

| Grade | C | Mn | Si | Cu | S | Cr | Fe | Ni | Co |

|---|---|---|---|---|---|---|---|---|---|

| Inconel Alloy 718 | 0.08 max | 0.35 max | 0.35 max | 0.3 max | 0.015 max | 17 – 21 | 6.00 – 10.00 | 50 – 55 | 1.0 max |

| Density | Melting Point | Tensile Strength | Yield Strength 0.2% Proof | Elongation (% in 50mm) (thick.>0.76mm) |

|---|---|---|---|---|

| 8.2 g/cm3 | 1350 °C (2460 °F) | Psi – 135,000 , MPa – 930 | Psi – 70,000 , MPa – 482 | 45 % |

Inconel 718 Coils Price, Inconel 718 Coils Density, Inconel 718 Coils Hardness, Inconel 718 Coils Composition, Inconel 718 Coils Heat Treatment, Inconel 718 Coils Yield Strength, Inconel 718 Coils Annealed, Inconel 718 Coils Exporters in India, Inconel 718 Coils ASTM B670, Inconel 718 Coils AMS 5596, High Strength Inconel 718 Coils, Inconel 718 Coils for Aerospace, Inconel 718 Coils for Marine, Inconel 718 Coils for Automotive, Inconel 718 Coils Distributors, Nickel Alloy 718 Coils, Buy Inconel 718 Coils Online, Inconel 718 Coils Stock in Mumbai, Inconel 718 Coils with Mill Test Certificate, Inconel 718 Coils for Petrochemical Industry, Inconel 718 Coils for Turbine Blades, Inconel 718 Coils Applications, Inconel 718 Coil Supplier India, Inconel 718 Coil Manufacturer USA, Inconel 718 Coil Thickness Range, Inconel 718 Cold Rolled Coils, Inconel 718 Hot Rolled Coils, Inconel 718 Coil Export to UAE, Inconel 718 Coil Dealers, Inconel 718 Coil Rate, Inconel 718 Coil Price per Kg, Inconel 718 Coil Stockholder, Inconel 718 Sheet and Coil, Inconel 718 Strip Coils, Inconel 718 Coil for Heat Exchanger

India

India United States

United States Saudi Arabia

Saudi Arabia Kuwait

Kuwait Singapore

Singapore Malaysia

Malaysia UAE

UAE Germany

Germany Italy

Italy China

China UK

UK Canada

Canada Iran

Iran Thailand

Thailand South Korea

South Korea Turkey

Turkey Morocco

Morocco Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines Egypt

Egypt Japan

Japan Russia

Russia Vietnam

Vietnam Australia

Australia Qatar

Qatar South Africa

South Africa Portugal

Portugal Oman

Oman Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Netherlands

Netherlands Indonesia

Indonesia Mexico

Mexico Brazil

Brazil France

France Taiwan

Taiwan Nigeria

Nigeria Bangladesh

Bangladesh Iraq

Iraq Ukraine

Ukraine Poland

Poland Romania

Romania Cyprus

Cyprus Angola

Angola Colombia

Colombia Norway

Norway Chile

Chile Tobago

Tobago Greece

Greece Czechia

Czechia Belgium

Belgium Sri Lanka

Sri Lanka Myanmar

Myanmar Venezuela

Venezuela