- Mon to Fri 9:00am to 6:00pm

- +91-9930066862

- info@metaaerospaces.com

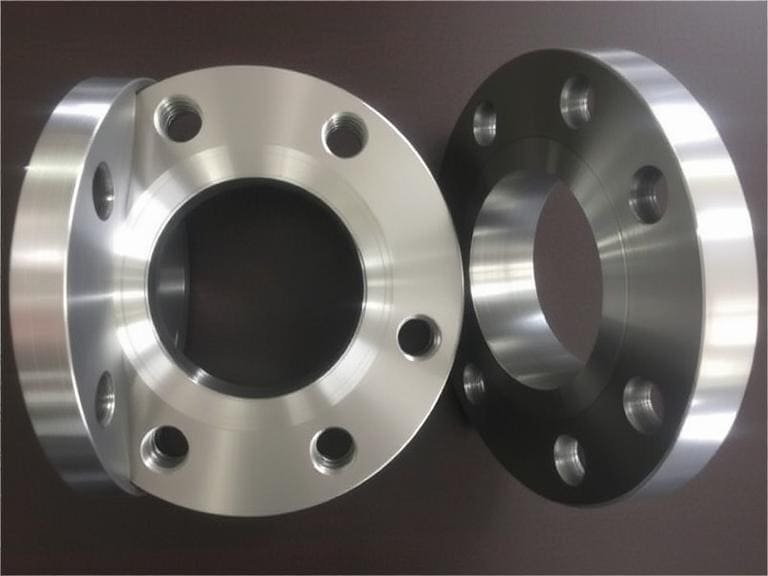

Meta Aerospace offers quality par excellence when it comes to supplying top-of-the-line industrial flanges, and our series of Inconel 625 Flanges leads the way with its superior strength and corrosion-resistant features. Made from top-grade nickel-chromium alloy, these flanges are engineered to perform in par excellence in harsh conditions. No matter if you have them installed for offshore platforms, chemical processing facilities, or power generation installations, these Inconel 625 Flanges are unmatchable in their strength and dependability. Not only do they work effectively under intense heat but also under hostile chemical conditions, making them the ideal option for installations that require enduring solutions.

Table of Content

Manufacturers of Inconel 625 Flanges such as Meta Aerospace concentrate on delivering flanges that have higher strength, fatigue life, and outstanding weldability. Inconel 625 superalloys are made of nickel with additives like chromium, molybdenum, and niobium that enhance their corrosion resistance and mechanical strength. The flanges are especially useful in resisting pitting, crevice corrosion, and stress corrosion crack. The flanges remain strong over a wide range of temperatures from cryogenic temperatures up to high temperatures of nearly 980°C, thus are widely used in different conditions in industry.

When it comes to the definition of Inconel 625 Flanges, they refer to precision-manufactured pipe fittings from the Inconel 625 alloy utilized for safely joining pipes, valves, pumps, and other equipment utilized in process piping systems. The flanges are manufactured in different types such as weld neck, socket weld, slip-on, blind, and threaded flanges, appropriate for both regular and high-pressure conditions. Their material provides them with oxidation, carburization, and other corrosive agents found in demanding industrial environments.

One of the most notable benefits of using Inconel 625 Flanges is their outstanding corrosion-resistant qualities in a broad spectrum of corrosive conditions. These include reducing and oxidizing acid, sea water environments, and intense thermal cycling. With low maintenance and long life, they minimize total life cycle costs of systems, representing an economic option for those requiring performance and reliability for their industry. In addition, these flanges have superb mechanical property retention subsequent to extensive periods of intense conditions, providing consistent functionality over their life.

Meta Aerospace is one of the reliable Suppliers of Inconel 625 Flanges that provide products according to specific industry needs. The flanges that we supply are greatly valued for their dimensional precision, tensile strength, and resistance towards aggressive chemicals and elevated temperatures. They possess a great fatigue strength and stress-rupture strength that enables them to be used in applications that are under dynamic stress and vibrations. Meta Aerospace has a quality control procedure with a zero-error approach, whereby each flange they supply meets with the international and domestic standards.

These flanges are utilized in reformer outlet manifolds, waste heat boilers, and process heaters in the Petrochemical Industry where there needs to be high oxidation and scaling resistance.

Being one of the prominent Inconel 625 Flanges Stockists in the market, Meta Aerospace provides instant availability and fast delivery of flanges with different sizes, specifications, and pressure classes according to the particular needs of customers. We have a wide inventory available for delivering exactly what our customers require. All these pieces go through thorough inspection and testing before they are shipped out, assuring peak performance under any conditions. We have become a trusted partner for customers from various sectors due to our quality commitment and services.

Meta Aerospace is also one of the reliable Inconel 625 Flanges Exporters that deliver products around the globe with focus on quality control, competitive prices, and on-time delivery. We export our flanges with complete documentation, third-party inspection, and as per international standards like ASTM B564. Our international presence keeps on growing as businesses around the globe are looking for trustworthy and high-quality performing Inconel 625 flange solutions.

| Standards | GOST Flange, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092, BS, BS4504, BS 10, EN-1092, DIN, ANSI, ASME, DIN, MSS S44, ISO70051, ANSI/ASME B16.5, ASME/ANSI B16.5/16.36/16.47A/16.47B, B16.47 Series A & B, B16.48, EN |

|---|---|

| Pressure Rating ANSI | Class 1500, Class 150, Class 900, Class 2500, Class 300, Class 600, |

| Pressure Calculation in DIN | 10Bar, 16Bar, 25Bar, 40Bar, 6Bar, / PN16, PN64, PN40, PN25, PN10, PN6 |

| JIS | 16 K, 20 K, 5K, 10 K, 40 K, 63 K, 30 K, |

| UNI | 10Bar 16Bar 6Bar 25Bar 40Bar |

| EN | 6Bar 25Bar 40Bar 10Bar 16Bar |

| Most common Types | Threaded / Screwed / Forged / Plate |

| Production technique | Forged, Heat treated and machined |

| Shapes and Types we produce | Large Male-Female (LMF), Ring Type Joint (RTJ), Flat Face (FF), Small Tongue, Small Male-Female (SMF),Raised Face (RF), Large Tongue & Groove, Groove, Lap-Joint Face (LJF) |

| Test | Direct-reading Spectrograph, Magnetic particle detector, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector |

| Equipment | Pushing Machine, Press machine, Bending machine, Sand-blasting machine, electric bevelling machine etc |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Inconel 625 | 8.4 g/cm3 | 1350 ?C (2460 ?F) | Psi ? 1,35,000 , MPa ? 930 | Psi ? 75,000 , MPa ? 517 | 42.5 % |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Inconel 625 | 8.4 g/cm3 | 1350 ?C (2460 ?F) | Psi ? 1,35,000 , MPa ? 930 | Psi ? 75,000 , MPa ? 517 | 42.5 % |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

|---|---|---|---|---|---|---|---|---|

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | 0.015 max | ? | 5.0 max | 58.0 min | 20.0 ? 23.0 |

Inconel 625 Flanges Dimensions, Inconel 625 Slip On Flanges, Inconel 625 Weld Neck Flanges, Inconel 625 Blind Flanges, Inconel 625 Socket Weld Flanges, ASTM B564 Inconel 625 Flanges, Inconel 625 Flanges Pressure Rating, Inconel 625 Raised Face Flanges, Inconel 625 Flanges Price List, Inconel 625 Flanges Weight Chart, Inconel 625 RTJ Flanges, Inconel 625 Screwed Flanges, Inconel 625 Lap Joint Flanges, Inconel 625 Orifice Flanges, Alloy 625 Flanges, Nickel Alloy 625 Flanges, Inconel Alloy 625 Flanges, Inconel UNS N06625 Flanges, Werkstoff Nr. 2.4856 Flanges, Inconel 625 Flanges for Marine Industry, Inconel 625 Flanges for Chemical Plants, High Pressure Inconel 625 Flanges, Inconel 625 Piping Flanges, Inconel 625 Forged Flanges, Industrial Inconel 625 Flanges, Custom Inconel 625 Flanges, ANSI B16.5 Inconel 625 Flanges, Inconel 625 Plate Flanges, Inconel 625 Flanges Exporter in India, Inconel 625 Flanges Supplier in Mumbai

India

India United States

United States Saudi Arabia

Saudi Arabia Kuwait

Kuwait Singapore

Singapore Malaysia

Malaysia UAE

UAE Germany

Germany Italy

Italy China

China UK

UK Canada

Canada Iran

Iran Thailand

Thailand South Korea

South Korea Turkey

Turkey Morocco

Morocco Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines Egypt

Egypt Japan

Japan Russia

Russia Vietnam

Vietnam Australia

Australia Qatar

Qatar South Africa

South Africa Portugal

Portugal Oman

Oman Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Netherlands

Netherlands Indonesia

Indonesia Mexico

Mexico Brazil

Brazil France

France Taiwan

Taiwan Nigeria

Nigeria Bangladesh

Bangladesh Iraq

Iraq Ukraine

Ukraine Poland

Poland Romania

Romania Cyprus

Cyprus Angola

Angola Colombia

Colombia Norway

Norway Chile

Chile Tobago

Tobago Greece

Greece Czechia

Czechia Belgium

Belgium Sri Lanka

Sri Lanka Myanmar

Myanmar Venezuela

Venezuela