- Mon to Fri 9:00am to 6:00pm

- +91-9930066862

- info@metaaerospaces.com

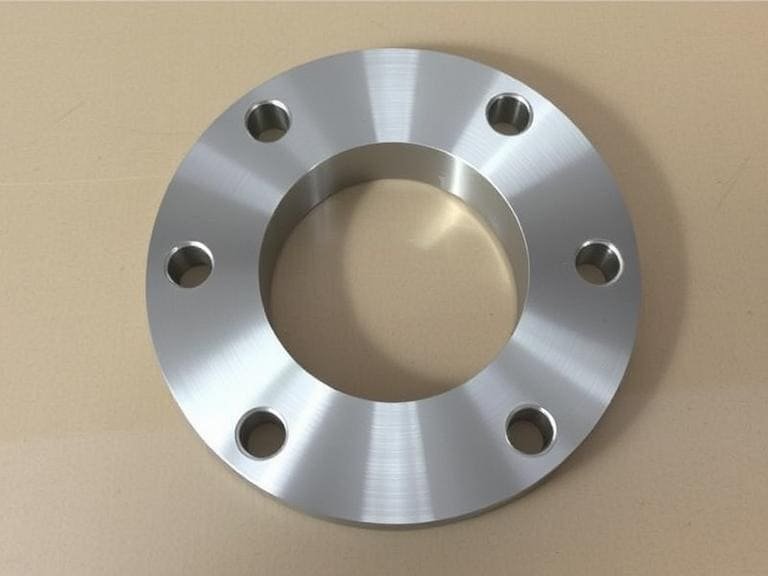

Inconel 718 Flanges are one of the most durable and highest performing alloy flanges for application in high-temperature and high-pressure environments. Meta Aerospace provides high-precision solutions with superior resistance towards elevated temperatures, corrosion, and stress corrosion cracking. The flanges are engineered from a nickel-base superalloy that includes niobium, molybdenum, iron, and chromium, thus making them ideal for application in aerospace, marine, oil and gas, and power generation.

Table of Content

At their essence, Inconel 718 Flanges are meant to possess exceptional mechanical properties both at lower and higher temperatures of up to 1300°F (704°C). Their fatigue strength as well as their resistance to post-weld cracking make them a prime option for numerous intricate engineering uses. Owing to its balanced chemistry, this alloy retains strength and integrity in the most hostile environments.

The applications of Inconel 718 Flanges have numerous benefits. They have superior tensile strength, fatigue life, creep life, and oxidation life. All these qualities render them extremely useful in hot service applications and heavy-duty pressure conditions. They also have outstanding resistance against chloride ion stress-corrosion cracking, pitting, and crevice corrosion that occur in aggressive service environments. The alloy also has the property of age-hardening, which enhances strength without any impact on weldability and formability.

Meta Aerospace excels among leading Inconel 718 Flanges Manufacturers with exceptional quality and reliability. We have flanges in numerous types like weld neck, slip-on, blind, socket weld, and threaded flanges, each of which conforms to international specifications like ASTM B564 and ASME SB564. We have effective production mechanisms in place that help our products undergo rigorous quality checks, assuring strength and functioning under tough conditions.

These flanges are utilized in reformer outlet manifolds, waste heat boilers, and process heaters in the Petrochemical Industry where there needs to be high oxidation and scaling resistance.

Being quality Inconel 718 Flanges Suppliers, Meta Aerospace provides timely supply of both custom and regular flanges for industries worldwide. Should you have small batches for testing or bulk quantities for full-scale operations, we serve varied needs with precision and care. We are a go-to source for critical applications in energy, aviation, and chemical industries due to our approach of catering to customers.

Meta Aerospace takes pride in being one of the top Inconel 718 Flanges Stockists with a vast inventory of finished flanges as well as semi-finished flanges available for same-day dispatch. We have an extensive range of sizes and pressure ratings in stock for fast delivery, making it possible for your projects to be completed according to deadlines. All flanges are traceable and are accompanied with full documentation and material test certifications.

Having extensive experience as Inconel 718 Flanges Exporters and a strong global presence, Meta Aerospace caters efficiently to its customers worldwide. We pack our products securely and send them with proper care so that they are delivered in perfect condition. We are aware of global logistics complexities and conform to all export regulations and standards for seamless transactions.

| Standards | GOST Flange, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092, BS, BS4504, BS 10, EN-1092, DIN, ANSI, ASME, DIN, MSS S44, ISO70051, ANSI/ASME B16.5, ASME/ANSI B16.5/16.36/16.47A/16.47B, B16.47 Series A & B, B16.48, EN |

|---|---|

| Pressure Rating ANSI | Class 1500, Class 150, Class 900, Class 2500, Class 300, Class 600, |

| Pressure Calculation in DIN | 10Bar, 16Bar, 25Bar, 40Bar, 6Bar, / PN16, PN64, PN40, PN25, PN10, PN6 |

| JIS | 16 K, 20 K, 5K, 10 K, 40 K, 63 K, 30 K, |

| UNI | 10Bar 16Bar 6Bar 25Bar 40Bar |

| EN | 6Bar 25Bar 40Bar 10Bar 16Bar |

| Most common Types | Threaded / Screwed / Forged / Plate |

| Production technique | Forged, Heat treated and machined |

| Shapes and Types we produce | Large Male-Female (LMF), Ring Type Joint (RTJ), Flat Face (FF), Small Tongue, Small Male-Female (SMF),Raised Face (RF), Large Tongue & Groove, Groove, Lap-Joint Face (LJF) |

| Test | Direct-reading Spectrograph, Magnetic particle detector, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector |

| Equipment | Pushing Machine, Press machine, Bending machine, Sand-blasting machine, electric bevelling machine etc |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| Inconel 718 | 2.4668 | N07718 | NCF 718 |

| Grade | C | Mn | Si | Cr | S | Fe | Mo | Ni | Cu |

|---|---|---|---|---|---|---|---|---|---|

| Inconel 718 | 0.08 max | 0.35 max | 0.35 max | 17.0–21.0 | 0.15 max | – | – | 50.0-55.0 min | 0.30 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.2 g/cm3 | 1.350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 482 | 45 % |

Inconel 718 Flanges, Inconel 718 Forged Flanges, ASTM B564 Inconel 718 Flanges, ASME SB564 Inconel 718 Flanges, High Strength Inconel 718 Flanges, Inconel 718 Blind Flanges, Inconel 718 Slip On Flanges, Inconel 718 Weld Neck Flanges, Inconel 718 Socket Weld Flanges, Inconel 718 Threaded Flanges, Inconel 718 Ring Type Joint Flanges, Inconel 718 Reducing Flanges, Inconel 718 Lap Joint Flanges, Inconel 718 Plate Flanges, Inconel 718 Long Weld Neck Flanges, Inconel 718 Flanges Pressure Rating, Inconel 718 Flanges Dimensions, Inconel 718 Flanges Price List, Inconel 718 Flanges Weight Chart, Inconel 718 Flanges Exporter India, Inconel 718 Flanges Supplier Mumbai, Inconel 718 Flanges Stockist in India, Inconel 718 Flanges Traders, Inconel 718 Flanges Chemical Composition, Inconel 718 Flanges Mechanical Properties, Inconel 718 Flanges Hardness, Inconel 718 Flanges for Petrochemical Industry, Inconel 718 Flanges for Power Plants, Inconel 718 Flanges for Offshore Platforms, Inconel 718 Flanges for Heat Exchangers, Inconel 718 Flanges for Refineries, Inconel 718 Flanges Distributor

India

India United States

United States Saudi Arabia

Saudi Arabia Kuwait

Kuwait Singapore

Singapore Malaysia

Malaysia UAE

UAE Germany

Germany Italy

Italy China

China UK

UK Canada

Canada Iran

Iran Thailand

Thailand South Korea

South Korea Turkey

Turkey Morocco

Morocco Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines Egypt

Egypt Japan

Japan Russia

Russia Vietnam

Vietnam Australia

Australia Qatar

Qatar South Africa

South Africa Portugal

Portugal Oman

Oman Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Netherlands

Netherlands Indonesia

Indonesia Mexico

Mexico Brazil

Brazil France

France Taiwan

Taiwan Nigeria

Nigeria Bangladesh

Bangladesh Iraq

Iraq Ukraine

Ukraine Poland

Poland Romania

Romania Cyprus

Cyprus Angola

Angola Colombia

Colombia Norway

Norway Chile

Chile Tobago

Tobago Greece

Greece Czechia

Czechia Belgium

Belgium Sri Lanka

Sri Lanka Myanmar

Myanmar Venezuela

Venezuela