- Mon to Fri 9:00am to 6:00pm

- +91-9930066862

- info@metaaerospaces.com

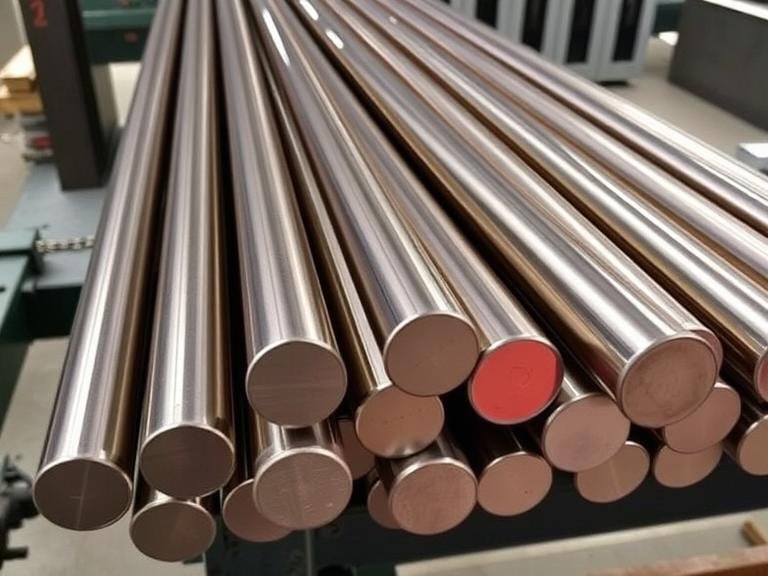

Meta Aerospace stocks high-quality Nimonic 105 Round Bar, designed for harsh environments where resistance to heat, stress, and corrosion is paramount. It is strengthened with titanium and aluminum in nickel-chromium-cobalt alloy, hence perfect for high-temperature service. It is made for aerospace, power generation, and high-stress applications where the round bars can resist huge thermal as well as mechanical loads without losing their strengths and integrity.

Table of Content

It is a superalloy designed specifically for demanding applications with high creep resistance and high tensile strength at high temperatures. It has a melting point of over 1300°C, making it work reliably in turbine blades, exhaust valves, and high-temperature bolts. Its chemical composition consists of about 60% nickel, 15% chromium, 20% cobalt, with additional quantities of molybdenum, aluminum, and titanium for increasing high-temperature strength as well as oxidation resistance.

Strengths of Nimonic 105 Round Bar include its performance at high temperatures. It is meant for thermal fatigue resistance, excellent mechanical properties, and high corrosion resistance. It has increased service life, even in hostile environments. Its high tensile strength makes it apt for aircraft engine structures as well as power plant components. Its oxidation resistance tends to minimize the need for maintenance and improves long-term stability in service.

The high tensile Nimonic 105 Round Bar is used in various industries due to its better mechanical profile:

Being one of the top-selling Nimonic 105 Round Bar Suppliers, Meta Aerospace provides international standards of precisely manufactured bars. We ensure that our production is uniform in material strength, dimensional accuracy, as well as surface finish appropriate for the most stringent requirements of the industry. We offer Nimonic 105 bars in different diameters as well as lengths, as per the customer requirements.

As one of the leading Nimonic 105 Round Bar Suppliers, the company aids important industries such as aerospace, defense, marine, and nuclear power. We ensure clients only get the best in terms of performance and reliability through stringent quality control as well as timely delivery.

As Meta Aerospace features extensive inventory as well as supply chain coverage, it ensures persistent material accessibility globally. Being reputed Nimonic 105 Round Bar Stockists, we have huge stocks in hand for fulfilling immediate project needs. We test our stock for mechanical property, non-destructive integrity, as well as dimensional accuracy. For any size custom bar or bulk stock, our ready stock reduces lead time as well as project delay.

Meta Aerospace is known as leading Nimonic 105 Round Bar Exporters, providing international markets with certified material with trustworthy logistics. We have global customers depending on our reliability, responsiveness, and technical competence in the delivery of high-performance Nimonic alloy solutions. Every shipment is documented, tested, and traceable for absolute compliance with industry standards.

| Dimensions | DIN, EN, ASTM, JIS, ASME, BS, AISI |

|---|---|

| Hex Bar Size | 2-100mm A/F |

| Round Bar Size | Diameter: 3-~800mm |

| Flat Bar Size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Angle Bar Size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Square Bar Size | 4 to 100mm |

| Channel Bar | 80 x 40mm to 150 x 90mm section; 5.0 to 6.0mm thickness |

| Rectangular Bars Section | 3.0 to 12.0mm thickness |

| Threaded Bar Billet Size | 1/2 to 495mm Diameter |

| Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Surface | Hot Rolled Pickled, Bright, Sand Blasting Finished, Cold Drawn, Hairline,Polished |

| Condition | Hardened & tempered, annealed |

| Technique | Cold Drawn, Hot Rolled, Forged Round Bar,Cold Rolled, Rod |

| Processing | Bar cutting to 650mm |

| Form | Rod, Round, Channel Bar, T-Bar, Flat Bar, Precision Ground Bar, Blocks, Square, Rings, Round Rod, Triangle, Hollow, Rectangle, Threaded, Hex (A/F), Profiles, Half Round Bar, Ingot, Billet, I/H Bar, Forging etc. |

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| Nimonic Alloy 105 | 2.4634 | N07090 |

| C | Si | Cu | Fe | Mn | Cr | Ti | Al | Co | Mo | Pb | S | B | Zr | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.12 | 1.0 | 0.2 | 1.0 | 1.0 | 14.0-15.7 | 0.9-1.5 | 4.5-5.5 | 18.0-22.0 | 4.5-5.5 | 0.0015 | 0.010 | 0.003-0.010 | 0.15 | Bal |

| Tensile Strength Minimum (psi) |

Yield Strength Minimum 0.2% offset (psi) |

% Elongation in 2″ Minimum |

|---|---|---|

| 167,000 | 112,000 | 25 |

Nimonic 105 Bar, Nimonic 105 Alloy Round Bar, High Strength Nimonic Bar, Nickel Alloy Round Bar, Nickel Chromium Cobalt Bar, Nimonic 105 Hex Bar, Nimonic 105 Flat Bar, UNS N13021 Round Bar, AMS 5824 Bar, Nimonic 105 Forged Bar, Heat Resistant Alloy Bar, Aerospace Grade Round Bar, High Temperature Nimonic Bar, Nimonic 105 Hot Rolled Bar, Cold Drawn Nimonic Bar, Superalloy Round Bar, Turbine Grade Nimonic Bar, Nimonic 105 Rod, Precision Ground Bar, Nimonic 105 Machined Bar, Engine Component Bar, Nimonic 105 Shafts, Alloy Round Rod, Corrosion Resistant Bar, Nimonic 105 Export Quality Bar, Nimonic 105 Bar Price, Buy Nimonic 105 Online, Nimonic 105 Material Supplier, Nimonic 105 Exporter India, ASTM Nimonic 105 Bar, Best Nimonic Bar Manufacturer, Nimonic 105 Inventory, Certified Nimonic 105, Alloy Nimonic Stock, Nimonic 105 Product Range, Nimonic 105 Steel Bar, Custom Size Nimonic Bar, Heavy Duty Nimonic Bar.

India

India United States

United States Saudi Arabia

Saudi Arabia Kuwait

Kuwait Singapore

Singapore Malaysia

Malaysia UAE

UAE Germany

Germany Italy

Italy China

China UK

UK Canada

Canada Iran

Iran Thailand

Thailand South Korea

South Korea Turkey

Turkey Morocco

Morocco Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines Egypt

Egypt Japan

Japan Russia

Russia Vietnam

Vietnam Australia

Australia Qatar

Qatar South Africa

South Africa Portugal

Portugal Oman

Oman Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Netherlands

Netherlands Indonesia

Indonesia Mexico

Mexico Brazil

Brazil France

France Taiwan

Taiwan Nigeria

Nigeria Bangladesh

Bangladesh Iraq

Iraq Ukraine

Ukraine Poland

Poland Romania

Romania Cyprus

Cyprus Angola

Angola Colombia

Colombia Norway

Norway Chile

Chile Tobago

Tobago Greece

Greece Czechia

Czechia Belgium

Belgium Sri Lanka

Sri Lanka Myanmar

Myanmar Venezuela

Venezuela