- Mon to Fri 9:00am to 6:00pm

- +91-9930066862

- info@metaaerospaces.com

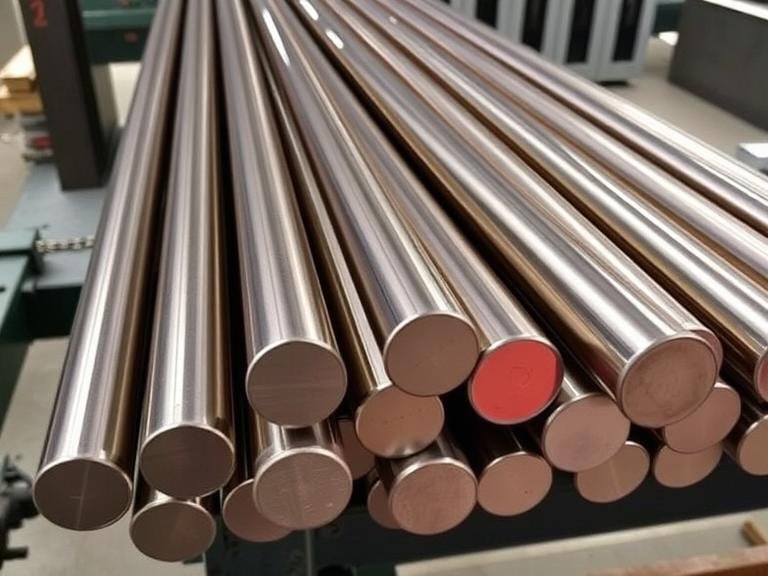

Meta Aerospace is the premier supplier of high-quality industrial alloys that is renowned for providing precision-engineered products for the most demanding challenges. Among our top products is the SMO 254 Round Bar, a high-performance austenitic stainless steel bar capable of withstanding harsh environments with excellent mechanical strength in addition to corrosion resistance.

Table of Content

The SMO 254 Round Bar is an alloy stainless steel with high molybdenum, nitrogen, and chromium content. Its structure is what makes it remarkably resistant to crevice corrosion, pitting, and stress corrosion cracking—specifically in environments containing high amounts of chloride. Increased nickel content is added for better formability as well as structural stability, increasing its formability as well as weldability, making it an ideal choice in various industries.

One of the key benefits of utilizing SMO 254 Round Bar is excellent resistance towards seawater, aggressive chemicals used in the industry, as well as brackish water environments. It is perfect for applications where corrosion resistance is critical. It has superior tensile strength as well as creep resistance at high temperatures, exceeding other popular stainless steel grades in the market such as 316L as well as 904L.

The high tensile SMO 254 Round Bar is used in various industries due to its better mechanical profile:

According to experts, desalination plants are dependent greatly on material quality, and SMO 254 Round Bar Suppliers serve this industry with bars whose integrity is sustained at high chloride as well as high-pressure environments. Their efficiency ensures long-term, without-interruption functioning in water treatment plants.

The SMO 254 Round Bar is prized for its formability as well as its weldability, so it may be shaped to fit your specifications without affecting performance. It is also nonmagnetic in permeability, suitable for applications involving sensitive electronics or magnets.

Meta Aerospace is committed to rigorous checks at each production stage and ensures timely delivery worldwide. We have round bars in various diameters as well as lengths, adapted according to client requirements. We stock uniformly in amounts enough to ensure immediate project requirements without any loss of time.

| Dimensions | DIN, EN, ASTM, JIS, ASME, BS, AISI |

|---|---|

| Hex Bar Size | 2-100mm A/F |

| Round Bar Size | Diameter: 3-~800mm |

| Flat Bar Size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Angle Bar Size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Square Bar Size | 4 to 100mm |

| Channel Bar | 80 x 40mm to 150 x 90mm section; 5.0 to 6.0mm thickness |

| Rectangular Bars Section | 3.0 to 12.0mm thickness |

| Threaded Bar Billet Size | 1/2 to 495mm Diameter |

| Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Surface | Hot Rolled Pickled, Bright, Sand Blasting Finished, Cold Drawn, Hairline,Polished |

| Condition | Hardened & tempered, annealed |

| Technique | Cold Drawn, Hot Rolled, Forged Round Bar,Cold Rolled, Rod |

| Processing | Bar cutting to 650mm |

| Form | Rod, Round, Channel Bar, T-Bar, Flat Bar, Precision Ground Bar, Blocks, Square, Rings, Round Rod, Triangle, Hollow, Rectangle, Threaded, Hex (A/F), Profiles, Half Round Bar, Ingot, Billet, I/H Bar, Forging etc. |

| STANDARD | WERKSTOFF NR. | UNS | SIS | AFNOR | EN |

|---|---|---|---|---|---|

| SMO 254 | 1.4547 | S31254 | 2378 | Z1 CNDU 20.18.06Az | X1CrNiMoCuN20-18-7 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Ti |

|---|---|---|---|---|---|---|---|---|---|

| SMO 254 | 0.2 max | 1.5 max | 0.75 max | 0.040 | 0.030 max | 18.00 – 22.00 | - | 0.50 max | – |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.0 g/cm3 | 1320-1390 ℃ | 650 | 300 | 35 % |

SMO 254 Bar, SMO 254 Rod, SMO 254 Bright Bar, ASTM A276 SMO 254 Round Bar, UNS S31254 Round Bar, Alloy 254 Round Bar, SMO 254 Hex Bar, SMO 254 Square Bar, SMO 254 Flat Bar, 254 SMO Stainless Steel Round Bar, SMO 254 Forged Bar, 254 SMO Cold Drawn Bar, SMO 254 Polished Bar, SMO 254 Round Rod, High Strength SMO 254 Bar, Duplex SMO 254 Bar, Marine Grade SMO 254 Bar, SMO 254 Round Bar for Oil & Gas, SMO 254 Round Bar for Desalination, SMO 254 Round Bar for Chemical Plants, SMO 254 Round Bar for Heat Exchangers, SMO 254 Machined Bar, SMO 254 Export Quality Bar, SMO 254 Round Bar Price, SMO 254 Round Bar Distributor, SMO 254 Industrial Bar, SMO 254 Round Bar Specifications, SMO 254 Stainless Steel Supplier, SMO 254 Round Bar Online, SMO 254 Round Bar Dimensions, Buy SMO 254 Round Bar, SMO 254 Round Bar Dealers, SMO 254 Bar Exporter in India, SMO 254 Round Bar Material, SMO 254 Steel Bar

India

India United States

United States Saudi Arabia

Saudi Arabia Kuwait

Kuwait Singapore

Singapore Malaysia

Malaysia UAE

UAE Germany

Germany Italy

Italy China

China UK

UK Canada

Canada Iran

Iran Thailand

Thailand South Korea

South Korea Turkey

Turkey Morocco

Morocco Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines Egypt

Egypt Japan

Japan Russia

Russia Vietnam

Vietnam Australia

Australia Qatar

Qatar South Africa

South Africa Portugal

Portugal Oman

Oman Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Netherlands

Netherlands Indonesia

Indonesia Mexico

Mexico Brazil

Brazil France

France Taiwan

Taiwan Nigeria

Nigeria Bangladesh

Bangladesh Iraq

Iraq Ukraine

Ukraine Poland

Poland Romania

Romania Cyprus

Cyprus Angola

Angola Colombia

Colombia Norway

Norway Chile

Chile Tobago

Tobago Greece

Greece Czechia

Czechia Belgium

Belgium Sri Lanka

Sri Lanka Myanmar

Myanmar Venezuela

Venezuela